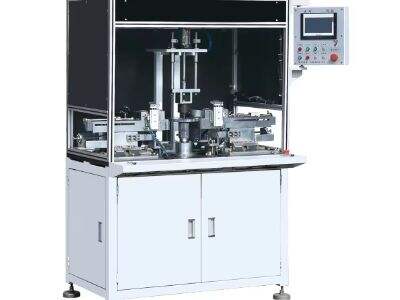

The machine consists of many different parts that all have their own role to play working in synchronous harmonic. A key component is the spindle. Spindle: This part holds the wire during the winding process. Another component Zhengma is a motor which turns the spindle. There are also guides to help guide the wire during the winding machine process. These guides ensure that the wire follows the proper path. It also incorporates sensors to monitor that all components are functioning. Thus, these sensors play a crucial role because the machine now needs to self-monitor its working and make corrections where needed

Why the Zhengma Method Preserves Quality

The new winding method that Zhengma has adopted is a very unique method, and it is mainly used to maintain the quality of coils and springs at very high levels. This technique is significant because companies want need each product sold to be of quality. The software in the machine has a special formula (an algorithm) that identifies the best winding methods for any required coil or spring. These formulas consider spindle speed, wire tension, and the number of inter-layer wraps

After processing this data, the software determines the way the wire must be wound around a spindle. This ensures that the coils and other springs are manufactured to the highest industry standards. Here is where the machine's sensors come into play. They track the winding as it occurs and give feedback to the machine. Should anything be off, the machinery itself can send alerts to the sensors to make adjustments. This guarantees the end product is excellent quality, every time

Why Zhengma Winding Machine Is Essential

Below are a few advantages of using Zhengma Fully Automatic coil winding equipment Machine in a factory. The most important thing is that the machine is very accurate. The identification of winding is conveniently managed via the software that controls the winding, so there is comparatively lower scope of mistake than manual operations. This means coils and springs that come out of this machine are always top notched and proper according to the requirement of any business

Secondly, the speed of the machine is extremely fast. As it is programmed, and powered through computer software, it can operate much faster than an individual ever could. Such speed is invaluable for businesses who need to crank out large numbers of coils and springs quickly. Manufacturers have to be able to create things quickly enough, as the modern-day world of manufacturing is an incredibly speedy one

The Secret to Great Winding

Excellent winding performance is The secret of Zhengma Fully Automatic Winding Machine, and its special fan winding machine method. It is this process that ensures that the coil and springs manufactured by the machine are of the exact same quality. This machine is a fast, reliable and high precision machine and it is ideal for coiling and spring production in bulk.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

HY

HY

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

TA

TA

MY

MY

KK

KK

UZ

UZ

KU

KU