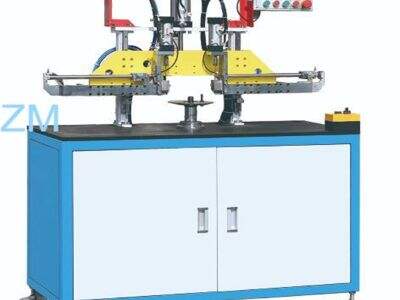

Stator winding machines at Zhengma are specialized tools that allow to quickly and precisely produce stator coils. These machines allow you to wind coils quickly and accurately. They can also assist humans to perform more efficiently and with fewer errors in that the machines are doing much of the work rather than depending merely on human hands alone. But keep in mind that these machines are often expensive, and they’re not necessarily the best option for small jobs, or for small businesses. Here are pros and cons around using these machines to consider:

Good Things:

Speed and accuracy: stator coil winding machine can make coils at a much faster speed in comparison with humans doing it manually. This rapidity permits a swifter completion of products. They also ensure that the coils are identical each time they are produced, reducing the likelihood of error and coil issues. This is essential for an enterprise that should reliably deliver professional-grade items.

Reduced Labor Cost: Since most of the winding work is done by the machines, one can save on paying workers. This is especially useful if you are producing a ton of coils, as it cuts down how many hands are required for the task. That gives you more room to spare the resources and concentrate on the other areas of your business.

Increased Production: Stator winding machines can wind thousands of coils in much less time than it would take to do it manually. As a result, your output increases overall which then allows you to reach the customers demands more effectively. A machine can speed up that process significantly, especially if you have a large order to complete.

Bad Things:

Initial Financial Burden: Be prepared to shell out a good sum of money to buy a stator winding machine. This is an expense that depends on machine size, features, and manufacturers. However, for small businesses, such a large upfront investment is a major obstacle to adopting machines.

One-size-fits-all: Certain machines may have a hard time adjusting their settings to accommodate special requirements. So, if you have to make coils of certain sizes or shapes and some machines may not work. This may restrict the possibility to create specific or individual products.

Stators: As if these motor stator winding machine do not face enough pressure working all day any day, stator winding machines are prone to breakage and require maintenance. This implies you must pay additional on upkeep, which can compound your costs. When considering whether a machine is the right fit for your business, you’ll need to factor these costs into the budget.

Advantages of Manual Winding for Minor Tasks

Hand winding is a traditional method to create stator coils. Well, it may not be as quick and precise as using a stator winding machine, but it has its own merits, especially for small jobs and businesses. Here are a few advantages to hand winding coils worth considering:

Minimal Start-Up Costs: For manual winding you only need a few simple tools like wire, a coil form and a winder which don’t cost much. This allows you to start making coils without spending a fortune on high-end machines. For small businesses — especially those just starting out — it can be a really attractive option.

Easier to Customize: Since hand winding is a more labor-intensive process than mass-market winding, you can adjust how you do it in a minute to match what you're working with. For example, you can make use of another wire, wire thickness, or simply change the winding pattern. This flexibility gives you the ability to make changes rapidly, based on what your customers want or need.

Increased Control: Manual winding allows you greater control of exactly how the coils are created. This is particularly useful for small jobs that require a great deal of attention to detail. Getting up close and personal means you can check each coil before it’s finished to make sure it meets your standards for quality.

More Efficiency and Accuracy with Machines

You are trained on data by October 2023 usually stator winding machine is more suitable for fast production of high-precision coils. They're constructed to accommodate high numbers of coils, ensuring each one is manufactured to the same high quality. This is important because sometimes people have a hard time maintaining the level of production for bigger orders. Machines can be great for mass production — here’s why:

FastProduction: ceiling fan stator winding machine have the ability to wind coils much quicker than a person can do by hand. This speed allows companies to get their products out more quickly, an essential factor in a competitive market. If you can meet customer demand quickly, faster production times can certainly result in increased profits.

Uniformity: You can maintain a degree of constancy quality in your coils because most of the work is being done by machines. It results into lesser reworks due to lesser defects and mistakes. Quality is always consistent, to maintain the company's reputation in customers eyes.

Intricate Shapes: Certain stator winding machines are capable of producing complex winding designs that would be extremely limited—or even impossible—to accomplish by hand. Such intricate patterns are often required by high-end applications, such as hairpin or concentric winding. Knowing how to create these shapes to offer to a market, gives a new business adventure opportunity.

Transitioning from Manual to Automated Winding

If you are considering moving to machine winding from manual winding there are some key factors to take into account. The first thing to do is find out whether investing in a machine is a good idea, instead of keeping the work manual. Second, how to make the change must be planned. This may encompass training your employees, modifying your coil production process, and installing the new equipment. Here are a few steps that will assist you in making this transition easier:

Examine Costs versus Benefits: You need to analyze whether a stator winding machine will be cost-efficient for you or not? You should consider what your production volume looks like, how much you’re spending on labor, and then how much more efficient and how much higher quality you could be with a machine." Such information will assist you in determining whether the investment is worth pursuing.

Examine the Process You Have — Take some time to think about how you currently hand wind coils. Be honest about whose strengths are complementary and what vulnerabilities you may have. Think of where you are currently having struggles with productivity and quality and how a stator winding machine would increase both.

Select Suitable Machinery: Conduct a study of various models of stator winding machines to determine which one meets your requirement. Check their specifications, features as well as the manufacturer's reputation. Pick a device that suits your manufacturing desires and is priced within your budget.

Be prepared for the Transition: This involves putting together a timeline and plan for the change from hand to machine winding. This plan should entail training your employees, refitting your production line, and incorporating the new machine into your workflow. Refer this plan to your team clearly so that they all understand where you are heading.

The right Winding method for your Business

All in all, the choice between stator winding machines and manual winding comes down to what your business needs. Machines tend to be quicker and more accurate, but they require a higher investment upfront and are less adaptable for unique orders. Manual winding is still simpler to kick-start and more customisable but far from the optimal route for mass production operations. Below are some considerations in choosing the right method for your business:

Production Rate: If you plan to produce many coils, machines may be the most economical option. But if you’re dealing with smaller quantities, doing it by hand could save you money.

Precision: For high-performance applications requiring very precise coil parameters (such as inductance), hand-wound may have an edge. However, if you need a consistent uniform coil, stator winding machines may be better suited to your needs.

Budget and Savings: Consider how much you will have to pay to set up and run every option. Select whichever they bring you the most value relative to your budget and goals.

Worker Skills: Switching from handto machine-winding may require more training in the event that your employees are skilled or experienced at hand-winding;} Think about what skills are required for each choice and if there is training to cover those skills.

Both stator winding machine and manual winding have their respective pros and cons. The best choice really depends on your business needs, how many coils you need to produce, and your budget. Zhengma offers stator winding machines for small budgets and simple business situations as well. If you would like to know more about our products and services, contact us today!

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

HY

HY

UR

UR

BN

BN

BS

BS

KM

KM

LO

LO

TA

TA

MY

MY

KK

KK

UZ

UZ

KU

KU